**Title: Metal Roof Machine – Model 6: Revolutionizing Metal Roof Panel Production**

—

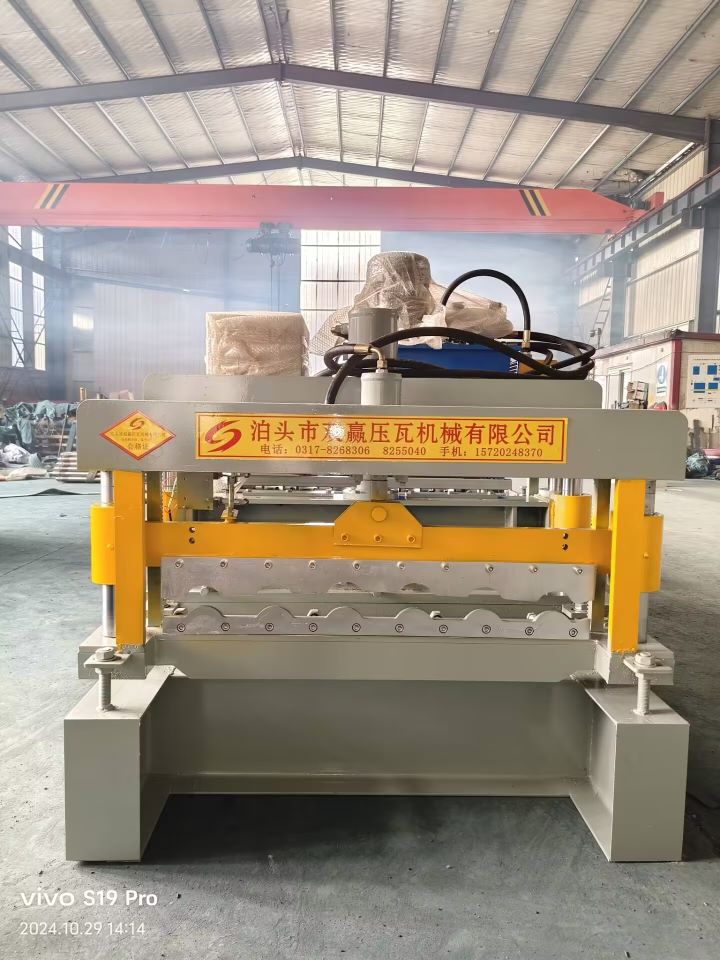

A **Metal Roof Panel Roll Forming Machine – Model 6** is a specialized piece of equipment designed to produce high-quality metal roof panels for residential, commercial, and industrial buildings. This machine leverages advanced roll forming technology to process metal coils into various roof panel profiles, including corrugated and standing seam panels. Its high automation, rapid production speed (ranging from 8 to 15 meters per minute), and exceptional product consistency make it an indispensable asset in the manufacturing of top-grade metal roofing systems.

### Overview of the Metal Roof Machine – Model 6

#### Simple Structure and Working Principle

**Decoiler**:

The decoiler holds and releases the metal coils, typically operated manually or hydraulically. It serves as the entry point for the metal sheets, feeding them into the roll forming system.

**Roll Forming System**:

Composed of multiple high-precision rollers, this system gradually shapes the metal sheet into the desired roof panel profile. The rollers are precisely engineered to ensure accuracy and durability during the forming process.

**Cutting System**:

Equipped with hydraulic or servo-controlled cutting devices, the cutting system ensures precise cuts and consistent panel lengths. This system operates automatically, reducing human error and enhancing efficiency.

**PLC Control System**:

The machine features a programmable logic controller (PLC) and a human-machine interface (HMI) for parameter setting and operation monitoring. The PLC system ensures precise control over the entire production process, from feeding the metal sheet to cutting the final panel.

**Drive System**:

Powered by a motor with chain or gear drive transmission, the drive system provides the necessary torque and speed to operate the machine efficiently.

**Output Table**:

The output table collects the finished panels, making them easy to package and transport. This feature enhances the overall productivity and ease of use of the machine.

#### Working Principle

1. **Decoiling**: The metal coil is placed on the decoiler, and the machine feeds it into the roll forming system.

2. **Roll Forming**: As the metal sheet passes through multiple rollers, it gradually takes the shape of the desired roof panel profile.

3. **Length Cutting**: The cutting system automatically cuts the panels to the specified length, as set in the PLC system.

4. **Output**: The finished panels are delivered to the output table, completing the production process.

This machine utilizes the ductility of metal, gradually shaping it through multiple roll passes. Its high efficiency, precision, and user-friendly interface make it an essential piece of equipment for producing metal roof panels.

### Steel Siding Machine for Sale

In addition to the Metal Roof Machine – Model 6, we also offer a specialized Steel Siding Machine for producing high-quality steel siding panels for residential, commercial, or industrial applications. These panels are commonly used for walls, roofs, and exterior cladding, providing durability and aesthetic appeal.

#### Key Features of Steel Siding Machines

– **Durable Frame**: Constructed with high-strength steel, typically 300mm H-beams, ensuring stability during operation.

– **Advanced Roll Forming System**: Equipped with hardened rollers to shape the steel sheet accurately without damage.

– **Customizable Designs**: Supports a variety of profiles, including ribbed, corrugated, or flat panels, catering to different aesthetic and functional requirements.

– **Automatic Control System**: Incorporates PLC (Programmable Logic Controller) for automated cutting, punching, and length adjustment, enhancing productivity and precision.

– **Production Speed**: Typically produces 8-15 meters per minute, depending on the profile, ensuring timely delivery of high-quality panels.

– **Energy Efficient**: Requires minimal power, often ranging from 6kW to 15kW, reducing operational costs.

#### Why Choose Our Steel Siding Machine?

– **High Quality**: Built with premium materials to ensure longevity and performance, ensuring your investment pays off in the long run.

– **Affordable Price**: Competitive pricing tailored for different budgets, making high-quality steel siding production accessible to everyone.

– **Customizable Options**: Machines can be customized to suit your specific requirements, ensuring you get exactly what you need for your project.

– **After-Sales Service**: A dedicated support team is available for installation guidance, maintenance, and troubleshooting, ensuring your machine runs smoothly and efficiently.

#### Applications

– **Residential Buildings**: Durable and attractive siding options for homes, enhancing curb appeal and property value.

– **Commercial Projects**: Cladding for warehouses, offices, and retail spaces, providing a professional and aesthetically pleasing appearance.

– **Industrial Uses**: Protective and aesthetic siding for factories and workshops, ensuring durability and functionality.

### For Inquiries

For more information about our Metal Roof Machine – Model 6 and Steel Siding Machine, please contact China Botou Win-Win Roll Forming Machine Co., LTD.

– **WhatsApp**: +8613832784260

– **Email**: zhaohuabb@163.com

– **Website**: www.cnwinmachine.com

Transform your projects with our high-performance metal roof and steel siding machines! 🚀